EN ISO 11612 certified Aluminized Fire Proximity Suit

- RNG Performance Materials

- Feb 13, 2024

- 2 min read

Updated: Mar 30, 2024

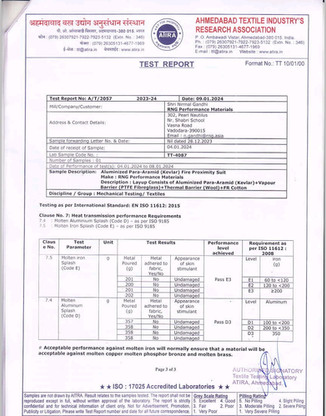

RNG Performance Materials has tested and certified its entire 4 layered Aluminized Para-Aramid suit layup to EN ISO 11612 test standard to the highest possible rating of A1, A2, B3, C4, D3 ,E3 ,F3.

Aluminized Para-Aramid Fire Suit also called as Aluminized Kevlar Fire Proximity Suit is used for fire protection, radiant heat & molten metal splash protection in oil & gas sector, power sector, thermal plant, foundries, iron & steel, aluminum & copper and gold & mining industries. It provides additional life & cut protection than Aluminized Fibreglass Fire suits and is a preferred option for radiant heat above 1100°C.

It is therefore essential that the entire fire suit layup be tested and certified to ensure the best fire protection, outstanding radiant heat protection & molten metal splash protection thereby giving the end user confidence in wearing the safety PPE.

Our Aluminized Fire Proximity Suit has been certified as per the EN ISO 11612 test certificate attached below:-

The fire resistance test involves exposing the Aluminized Fabric Layup to direct flame and ensuring the same does not catch or propagate the fire as shown in the video below

The radiant heat, convective heat & contact heat testing involves exposing the Aluminized Fire Suit layup to extreme temperatures as stated in the test standard and thereafter measuring the capacity to withstand the heat as shown in the video below

The molten metal testing involves splashing the molten metal over the Aluminized Fire Proximity Suit and checking the bio-skin under the layup for any burn marks as shown in the video below

RNG Performance Materials ensures the product is duly tested and certified fit for use through rigorous testing as shown in the videos above.

Aluminized Para-Aramid Fire Proximity suit consist of Hood with Visor, Jacket with BA Pouch, Pant, Gloves and Leg Guard. Optionally we can also provide EN 166 / EN 171 Gold Coated Visor and Overboots. Aluminized Para-Aramid can also be used to make Aprons & Back Open Coat.