Fire Tests Certificates & their Significance

- RNG Performance Materials

- Mar 24, 2020

- 3 min read

Updated: Jan 21, 2021

This article will give you an overview of the various fire tests certificates applicable to high temperature fire safety PPE and fire blankets. To select your product you need to review these fire standards so that relevant products are used as per the user application.

IS 11871 : Vertical Flammability

This is an Indian fire test standard where the fabric sample is exposed to a vertical flame for 12 seconds and parameters such as flashing, duration of flame on the sample, afterglow, char length and whether there is any abnormal behaviour or not. Any fabric used in a fire blanket or fire PPE should not have any flashing, duration of flame or any sort of abnormal behaviour. A typical certificate is shown here.

Any fire blanket or welding blanket must as a bear minimum be certified to IS 11871.

Fiberglass Fabrics, Silicone Coated Fiberglass, Vermiculite Coated Ceramic and High Silica fabric pass this tests.

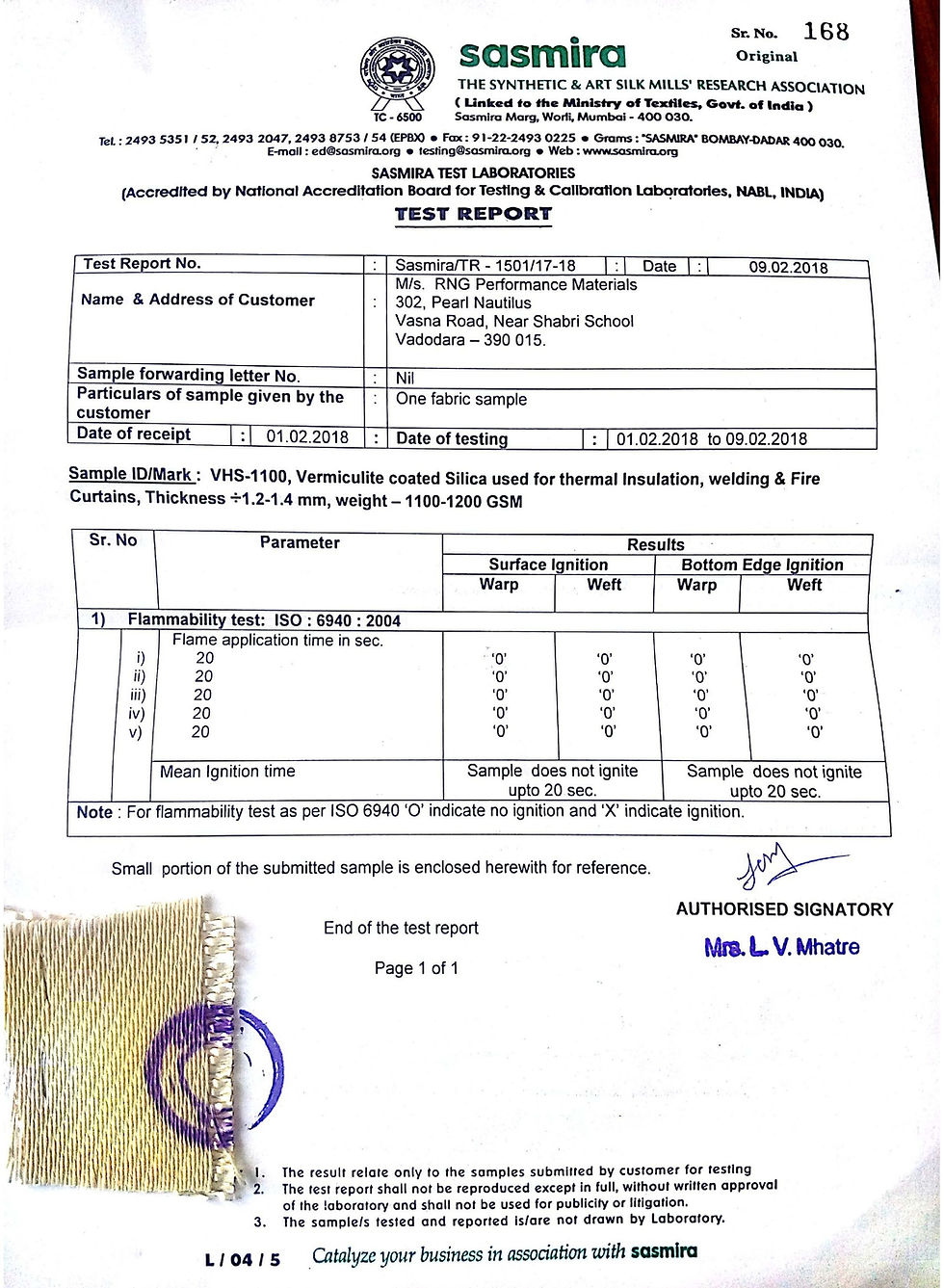

ISO 6940: Flammability Tests

It is an international standard flammability tests where the surface and edge ignition of the fabric is tested on exposure to 20 seconds of flame. Sample must not ignite upto 20 seconds to pass this standard. An example of the test report has been shown here.

A fire blanket fabric used for welding certified to ISO 6940 gives the added performance guarantee to the end user.

Vermiculite Coated Ceramic and High Silica fabric pass this tests.

BS EN 45545 & BS EN 13501: Combustibility and Fire Tests

This is one of the most difficult fire tests for checking the combustibility and fire properties of fabrics used in construction products and building materials as well as fabrics used for railways application which can be exposed to high heat and extreme fire. Test report shown here.

Any fire blanket used for high duration and close proximity welding blankets in construction or railway industry should be certified to this standard.

Only the High Silica fabrics are approved to these standards.

FM 4950: Welding Tests

This is a specialized tests particularly designed for fabrics which are supposed to withstand welding sparks.

Welding blankets can be approved to FM standards as an additional certificate to guarantee performance.

The high silica fabrics of 600 and 1100 gsm are certified to this standard.

ISO 15025 Ignition Tests for Limited Flame Spread

This is the most important tests for Aluminized Fire Safety Clothing and it applies a flame on the surface and bottom of the fabric to check if any flaming occurs, whether there is any afterglow, any debris and whether a hole develops or not. An Aluminized Fabric must comply to this test.

Both Aluminized Kevlar and Aluminized Fiberglass comply to this standard.

EN ISO 11612 Tests

This standard tests the Aluminized Fiberglass to the following parameters:

Surface Ignition : Code A

Convective Heat : Code B

Radiant Heat : Code C

Molten Aluminium Splash : Code D

Molten Iron Splash : Code E

Contact Heat : Code F

Regular Aluminized Fiberglass is certified to A1 , B1 , C3

Dual Mirror Aluminized Fiberglass with inner FR layer is certified to A1, B2, C4, D2, E3, F1

Aluminized Kevlar is Certified to A1, B1, C3, D3, E3, F1

So as you could see each type of application and severity of the fire/flames/molten metal and radiant heat warrants a different kind of certification to which the concerned fabric must be approved.

For further clarifications regarding certification for each product kindly contact us on Sales@RNG.Asia